Home » Products »Gypsum Powder Production Line » Phosphorus Gypsum Production Line »

Phosphogypsum Equipment

Product List

- Gypsum Board Production Line

- Gypsum Powder Production Line

- Gypsum Powder Machine

- FGD Gypsum Production Line

- Phosphorus Gypsum Production Line

- Gypsum Block Production Line

- Gypsum Board PVC Ceiling Tile Machine

- Ceiling Tile T-Grid Machine

- Gypsum Mixing Machine

- Gypsum Board Raw Material

- Modified Starch

- Gypsum Board Paper

- Gypsum Board White Latex

- Foaming Agents for Gypsum Boards

- Water Reducing Agent

- Gypsum Retarding Agent

- Gypsum Accelerator

- Gypsum Ceiling Tile Material

- Gypsum Board

- PVC Film

- PET Foil

- White Glue for Plaster Ceiling Board

- Gypsum Powder Additives

- Citric Acid

- Cellulose for Gypsum

- Glue Powder

- Starch Ether

Phosphogypsum Equipment

Description

Our phosphogypsum equipment adopts distributed control system (DCS), which greatly reduces the number of operators, thereby effectively reducing labor costs. High efficient dust collectors are utilized to reduce dust concentration.Technology of Phosphorus Gypsum Machine

Two-step treatment. The first step is to remove the free water in the phosphogypsum raw material (the process is also called preheating). Hot air and phosphogypsum raw material is mixed during going through hot air tube. The second step is to remove part of the crystal water in the preheated phosphogypsum.Phosphogypsum Equipment Capacity

| Capacity/year | Capacity/hour | Raw Material Consumption | Calcinor Size |

| 30,000 tons/year | 4.2 tons/hour | 45,000 tons/year | 4.5 × 1.2 × 1.4 m |

| 50,000 tons/year | 6.9 tons/hour | 75,000 tons/year | 4.5 × 1.4 × 1.6 m |

| 60,000 tons/year | 8.3 tons/hour | 90,000 tons/year | 4.5 × 1.6 × 1.8 m |

| 100,000 tons/year | 13.88 tons/hour | 150,000 tons/year | 4.5 × 2.0 × 2.2 m |

| 150,000 tons/year | 20.83 tons/hour | 225,000 tons/year | 4.5 × 2.2 × 2.4 m |

| 200,000 tons/year | 27.77 tons/hour | 300,000 tons/year | 4.5 × 2.4 × 2.6 m |

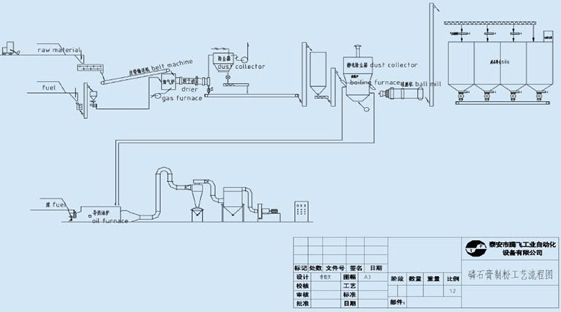

Technology Process of Phosphorus Gypsum Machine

Installation of Phosphogypsum Equipment and Training to Operators

1. Engineers and technicians from our company will be dispatched to the installation site to give instruction in the installation and commissioning work.2. The buyer shall supply welding workers and fitters to cooperate in the work of installation and commissioning.

3. During the installation and commissioning, the buyer’s operators will be trained in respect of operation, trouble-shooting and maintenance by the technicians and engineers.

Related Products

-

-

Phosphogypsum Plant

Phosphogypsum plant is composed of hot air furnace, preheating system, calcining system, dust collecting system, modifying system, conveying system, packing system and storage system. ...