Product List

- Gypsum Board Production Line

- Gypsum Powder Production Line

- Gypsum Powder Machine

- FGD Gypsum Production Line

- Phosphorus Gypsum Production Line

- Gypsum Block Production Line

- Gypsum Board PVC Ceiling Tile Machine

- Ceiling Tile T-Grid Machine

- Gypsum Mixing Machine

- Gypsum Board Raw Material

- Modified Starch

- Gypsum Board Paper

- Gypsum Board White Latex

- Foaming Agents for Gypsum Boards

- Water Reducing Agent

- Gypsum Retarding Agent

- Gypsum Accelerator

- Gypsum Ceiling Tile Material

- Gypsum Board

- PVC Film

- PET Foil

- White Glue for Plaster Ceiling Board

- Gypsum Powder Additives

- Citric Acid

- Cellulose for Gypsum

- Glue Powder

- Starch Ether

Gypsum Block Production Line

Description

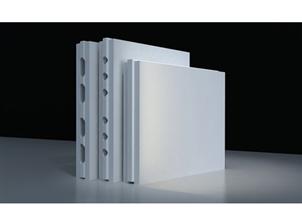

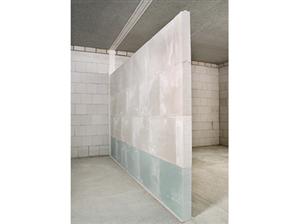

Gypsum block is a massive lightweight building material for building fire-resistant interior walls, partition walls, cavity walls, skin walls and pillar casing indoors. Gypsum block is composed of solid gypsum plaster, water and additives (like vegetable, wood fiber).Partition wall is made from gypsum blocks for erection. Gypsum adhesive is used as bonding agent not regular mortar. Because of this fundamental difference, gypsum blocks should not be confused with the thinner plasterboard (it also known as wallboard or gypsum board), which is used for paneling stud walls.

Application of Gypsum Block Machine

The gypsum block production line is composed of conveyor, weighing machine for water, weighing machine for gypsum, mixer, moulding, hydraulic system, grip, and control panels.Features of Gypsum Block Machine

Fully automaticChrome coated moulding surface

Environment-friendly

Accurate size of the block

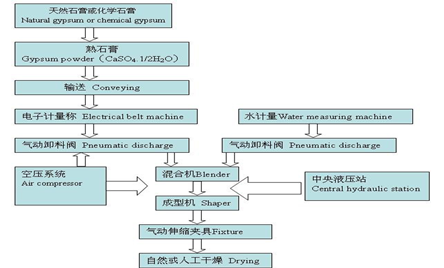

Working Process of Gypsum Block Production Line

The basic process of making gypsum is: weighing gypsum and water —— mixing —— setting —— lifting ——gripping —— dryingGypsum Block Machine Capacity

| Capacity/year | Block Length | Block | Block Thick | Blocks/Batch | Batches/hour |

| 100,000sqm | 666 mm | 500 mm | 80-150 mm | 7 blocks | 6 batches |

| 200,000sqm | 666 mm | 500 mm | 80-150 mm | 14 blocks | 6 batches |

| 300,000sqm | 666 mm | 500 mm | 80-150 mm | 21 blocks | 6 batches |

Typical Process of Gypsum Block Production Line

Installation of Gypsum Block Production Line and Training to Operators

1. Engineers and technicians from our company will be dispatched to the installation site to give instruction in the installation and commissioning work.2. The buyer shall supply welding workers and fitters to cooperate in the work of installation and commissioning.

3. During the installation and commissioning, the buyer’s operators will be trained in respect of operation, trouble-shooting and maintenance by the technicians and engineers.

Related Products

-

-

Gypsum Board Production Line

The gypsum board production line (plasterboard machine) is composed of raw material batching system, mixer, board forming station, board setting line, cut-off knife, transfer table, dryer, booking machine, trimming machine and stacker. ...

-

-

Gypsum Powder Production Line

The raw material of gypsum powder can be from natural gypsum rock, phosphogypsum, FGD (flue-gas desulfurization). The gypsum powder production line (gypsum plaster machine) is composed of crushing system, grinding system, calcining system, energy supply system, conveying system, packing system and storage system. ...

-

-

Gypsum Board PVC Ceiling Tile Machine

Gypsum board PVC ceiling tile machine is based on the paper faced gypsum board with thickness of 6 mm to 8 mm, spread with special glue on both side, then laminated PVC film and PET foil. After laminating, the board is cut into smaller size: 60 × 60 mm. The plasterboard PVC laminating production line is composed of board loading machine, glue spreader, laminating machine, press, lengthwise cutter, widthwise cutter, side taping machine, stacker, shrinking and packing machine. ...

-

-

Ceiling Tile T-Grid Machine

The ceiling tile T-grid machine is composed of manual decoiler, entry beach, main roll forming machine, shearing machine, hydraulic station, computer control station, product collecting table and punch press. ...