Product List

- Gypsum Board Production Line

- Gypsum Powder Production Line

- Gypsum Powder Machine

- FGD Gypsum Production Line

- Phosphorus Gypsum Production Line

- Gypsum Block Production Line

- Gypsum Board PVC Ceiling Tile Machine

- Ceiling Tile T-Grid Machine

- Gypsum Mixing Machine

- Gypsum Board Raw Material

- Modified Starch

- Gypsum Board Paper

- Gypsum Board White Latex

- Foaming Agents for Gypsum Boards

- Water Reducing Agent

- Gypsum Retarding Agent

- Gypsum Accelerator

- Gypsum Ceiling Tile Material

- Gypsum Board

- PVC Film

- PET Foil

- White Glue for Plaster Ceiling Board

- Gypsum Powder Additives

- Citric Acid

- Cellulose for Gypsum

- Glue Powder

- Starch Ether

Gypsum Board Production Line

Description

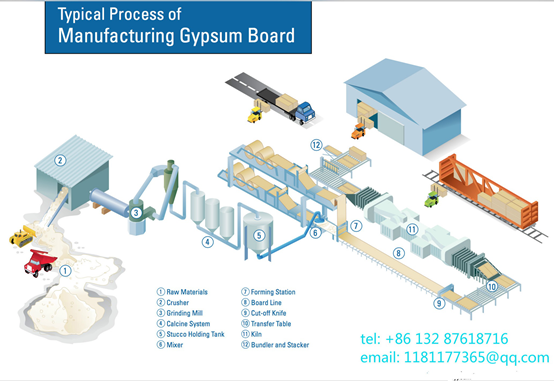

The gypsum board production line (plasterboard machine) is composed of raw material batching system, mixer, board forming station, board setting line, cut-off knife, transfer table, dryer, booking machine, trimming machine and stacker.Plasterboard production line works as often as necessary without consuming energy. Gypsum is the ideal surface for a wall because it has the same PH value and thermal conductivity properties as the human skin. Building materials made of gypsum always feel warm when touched. Gypsum board machine is no deception because gypsum possesses low thermal conductivity properties. As a result, gypsum building materials store has a warm feel.

Classification of Plasterboard Machine

Based on the application areas of the gypsum board, gypsum board production line is categorized into three: regular gypsum board, fire resistant gypsum board and moisture resistant gypsum boardThe gypsum board size varies with countries

Board Length: 1.5 to 4 meters (adjustable)Board Width: 1.2 m or 1.22 meters

Board Thickness: 7 mm to 20 mm (adjustable)

Features of Plasterboard Machine

1. The feeding speed of gypsum stucco, water and additives is controlled automatically and precisely, which ensures the accurate supply of all kinds of raw materials and saves labor cost.2. IPC and PLC can achieve communication, which share data with each other to make central control. All data can be shown on computer monitor and inspection can be done through computer.

4. Hot air drying technology is adopted in the drying system. It ensures the temperature in each deck of the dryer same either.

5. The gypsum board is evenly dried and it makes the production line more energy-saving.

Gypsum Board Production Line Capacity

| Capacity | Sheets Per Day (1200 × 2400 × 9 mm) | Dryer Decks | Control System |

| 2 million sqm/year | 2300 sheets/day | 4 decks | PLC |

| 4 million sqm/year | 4600 sheets/day | 6 decks | PLC |

| 6 million sqm/year | 6900 sheets/day | 8 decks | DCS |

| 10 million sqm/year | 11500 sheets/day | 10 decks | DCS |

| 20 million sqm/year | 23000 sheets/day | 12 decks | DCS |

| 30 million sqm/year | 34500 sheets/day | 12 decks | DCS |

Basic Formula of Gypsum Board Production Line (board thickness: 9.5 mm)

| Raw Material | Consumption | Raw Material | Consumption |

| Gypsum Stucco | 6.8kg/sqm | Foam Agent | 0.008kg/sqm |

| Paper | 0.48kg/sqm | White Latex | 0.005kg/sqm |

| Modified Starch | 0.035kg/sqm | Water | 4.8kg/sqm |

(The formula will be adjusted according to the working raw material quality and local production situation.)

Typical Process of Plasterboard Machine

Installation of Gypsum Board Production Line and Training to Operators

1. Engineers and technicians from our company will be dispatched to the installation site to give instruction in the installation and commissioning work.2. The buyer shall supply welding workers and fitters to cooperate in the work of installation and commissioning.

3. During the installation and commissioning, the buyer’s operators will be trained in respect of operation, trouble-shooting and maintenance by the technicians and engineers.