Product List

- Gypsum Board Production Line

- Gypsum Powder Production Line

- Gypsum Powder Machine

- FGD Gypsum Production Line

- Phosphorus Gypsum Production Line

- Gypsum Block Production Line

- Gypsum Board PVC Ceiling Tile Machine

- Ceiling Tile T-Grid Machine

- Gypsum Mixing Machine

- Gypsum Board Raw Material

- Modified Starch

- Gypsum Board Paper

- Gypsum Board White Latex

- Foaming Agents for Gypsum Boards

- Water Reducing Agent

- Gypsum Retarding Agent

- Gypsum Accelerator

- Gypsum Ceiling Tile Material

- Gypsum Board

- PVC Film

- PET Foil

- White Glue for Plaster Ceiling Board

- Gypsum Powder Additives

- Citric Acid

- Cellulose for Gypsum

- Glue Powder

- Starch Ether

Plaster Block Production Line

Description of Gypsum Block Plant

Partition wall is made from gypsum blocks for erection. Gypsum adhesive is used as bonding agent not regular mortar. Because of this fundamental difference, gypsum blocks should not be confused with the thinner plasterboard (it also known as wallboard or gypsum board), which is used for paneling stud walls.Application of Gypsum Block Plant

Plaster block production line is widely used for building, plaster block is as inner partition wall, because of its advantages of light weight, exact dimension, fire-proof function, shock-proof function, heat preservation and heat insulation, adjusting indoor's dryness and humidity, good capability of manufacture and convenient construction, etc.Plaster Block Production Line Capacity

| Capacity/year | Block Length | Block | Block Thick | Blocks/Batch | Batches/hour |

| 100,000sqm | 666 mm | 500 mm | 80-150 mm | 7 blocks | 6 batches |

| 200,000sqm | 666 mm | 500 mm | 80-150 mm | 14 blocks | 6 batches |

| 300,000sqm | 666 mm | 500 mm | 80-150 mm | 21 blocks | 6 batches |

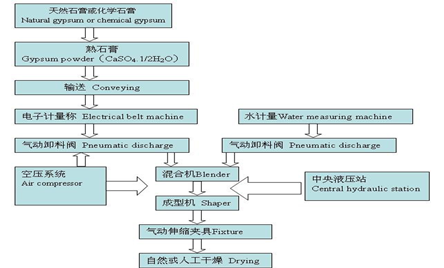

Work Process of Plaster Block Production Line

1. The gypsum in the material storage house is sent to the weighing bin through a screw conveyor, and the screw conveyor will stop when the amount of materials in the weighing bin reaches the set value.2. The water of the plant pipe network is sent to the weighing tank, which is controlled by solenoid valve. When the amount of water in the tank reaches the set value, the solenoid valve will be closed.

3. The weighed gypsum is quickly conveyed to the mixer by the screw conveyor, and water is transported to the mixer via the pneumatic valve.

4. After being mixed, the gypsum slurry is dumped into the forming machine. When the gypsum slurry achieves certain strength, a hydraulic scrapping device is used to scrape a rabbet and then eject the formed gypsum block through hydraulic pressure.

5. After this, the two-dimensional space clamp is used to clamp the gypsum block from the forming machine to the dryer. The water of the formed gypsum block can be removed by two methods: natural drying and artificial drying.

6. Finished Product Packaging and Storing Section

The dried gypsum block is unloaded and sent to the packaging machine through the unloading machine.

Related Products

-

-

Gypsum Block Equipment

Our self-developed gypsum block dryer is a tunnel drying machine which uses cross wind technology. The drying time is 36 hours. This dryer can use many types of fuels, including coal, natural gas, diesel, heavy oil, etc. Besides, gypsum block equipment is equipped with pusher, waste heat recovery system, automatic wind and temperature regulation system, steering machine, unloading machine, and subsystem, which help realize automatic running of the dryer. ...