Product List

- Gypsum Board Production Line

- Gypsum Powder Production Line

- Gypsum Powder Machine

- FGD Gypsum Production Line

- Phosphorus Gypsum Production Line

- Gypsum Block Production Line

- Gypsum Board PVC Ceiling Tile Machine

- Ceiling Tile T-Grid Machine

- Gypsum Mixing Machine

- Gypsum Board Raw Material

- Modified Starch

- Gypsum Board Paper

- Gypsum Board White Latex

- Foaming Agents for Gypsum Boards

- Water Reducing Agent

- Gypsum Retarding Agent

- Gypsum Accelerator

- Gypsum Ceiling Tile Material

- Gypsum Board

- PVC Film

- PET Foil

- White Glue for Plaster Ceiling Board

- Gypsum Powder Additives

- Citric Acid

- Cellulose for Gypsum

- Glue Powder

- Starch Ether

Gypsum Panel Production Line

Description

Gypsum panel production line (gypsum wallboard equipment) is fully automatic. Nature has presented us with a highly effective moisture management system in gypsum.Features of Gypsum Panel Production Line

1. The feeding speed of gypsum stucco, water and additives is controlled automatically and precisely, which ensures the accurate supply of all kinds of raw materials and saves labor cost.2. IPC and PLC can achieve communication, which share data with each other to make central control. All data can be shown on computer monitor and inspection can be done through computer.

4. Hot air drying technology is adopted in the drying system. It ensures the temperature in each deck of the dryer same either.

5. The gypsum board is evenly dried and it makes the production line more energy-saving.

Raw Materials Consumption for per Square Meter Gypsum Panel Production Line

| Land Plaster | 6.8kg/m2 |

| Shielding Paper | 0.48kg/m2 |

| Modified Starch | 0.035kg/m2 |

| Foaming Agent | 0.008kg/m2 |

| Glue | 0.005kg/m2 |

| Fiberglass (Not need badly) | 0.025kg/m2 |

| Electricity | 0.3kwh/m2 |

| Water | 4.8kg/m2 |

| Heavy oil: 11000kcal/kg | Heat consumption: 3800kcal/m2 |

| Natural gas: 8500kcal/ m3 | Heat consumption: 3800kcal/m2 |

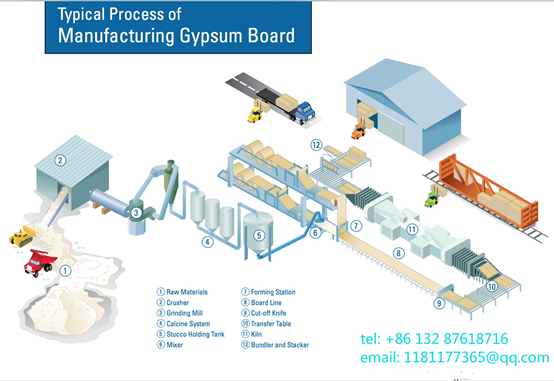

Typical Process of Gypsum Wallboard Equipment